SWAS design

Steam sampling and analysis design

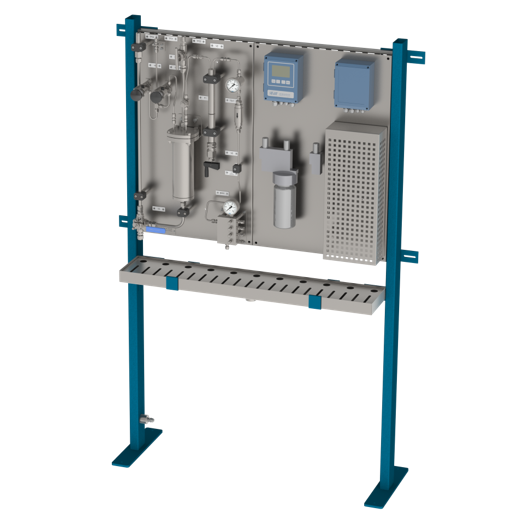

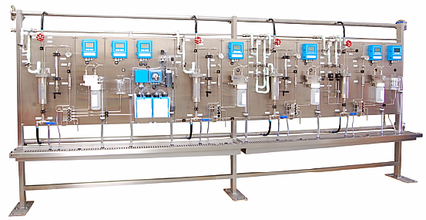

Mechatest is well known for it’s excellent design of water, steam sampling and analysis solutions (SWAS) built as per ASME PTC 19.11 and VGB S-006.

We take care of your steam sample from sample tab to lab!

The Steam and Water Analysis Systems (SWAS) are designed conform latest modern technology and has been continuously improved to keep the reability of your water steam analysis safe at all times and to protect your plant from corrosion and scaling.

We built state-of-the-art SWAS systems for modern power plants, with reliable components and measuring instruments, ease of maintenance and low cost of ownership.

Mechatest is an engineering company, we are a lot more than only hands for assembling of the SWAS systems, we provide advise, concepting, engineering, calculations (pressure drop, lagtime in the complete system, temperature and cooling capacity, sample probe resonance etc.), assembling and testing.

Our solutions are suitable for outdoor use in an industrial environment and ATEX Zone 1 or 2. After selecting the analysers and designing the sample systems it is very important to choose the environment for the complete system.

- Built as per standard VGB/DGRL and guidance ASME PTC 19.11 Steam and Water Sampling, Conditioning, and Analysis in the Power Cycle.

- Compact design with best selection of top of the world fabricate components

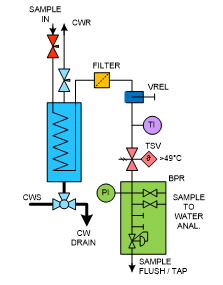

- Efficient temperature cooling with Sentry sample coolers, pressure reduction with Sentry VREL and flow control

- Grab sample capability

- Including Swan Back Pressure Regulator BPR for constant pressure and sample flow for up to 4 water analyzer applications

- Custom options are available to fit your needs

- Manufactured by Mechatest Sampling Solutions.

As an independent System Integrator our main activities are the complete design, engineering, procurement, assembly and integration of steam and water sampling, conditioning, and analysis systems for the power cycle industry, we design accordingly to VGB/DGRL and ASME PTC 19.11 which discuss the methods and instrumentation for testing boiler make-up and feedwater, steam, and condensate in relation to performance testing.

- Reliable / stable measurement

- A good working environment for monitoring and maintenance

- Lower maintenance costs

- Longer lifespan of the equipment, etc.

- In a lot of cases a “walk-in” shelter is a very good and durable solution.

- Steam apllications Demi Water, Feedwater, Condensate, Boiler Water, LP Drum Water, LP/HP Steam, Life Steam, Main Steam Demi Water, Feedwater, Condensate, Boiler Water, LP Drum Water, LP/HP Steam, Life Steam, Main Steam for power stations. Representative steam samples, Contamination free process and Custom build solutions. Control Your Steam Quality, increase lifetime of your steam applications, prevent corrosion in boilers and pipelines.

- Steam and Water Analysis System (SWAS), Analysis of pH, Conductivity, Silica, Sodium, Dissolved Oxygen, Phosphate, Chlorides, TOC for power stations

- etc.

- ASME PTC 19.11 Steam and Water Sampling, Conditioning, and Analysis in the Power Cycle

- ASME PTC 19.11-2008 Steam and Water Sampling, Conditioning, and Analysis in the Power Cycle

- VGB/DGRL, VGB S-006 Sampling and Physico-Chemical Monitoring of Water and Steam Cycles

- VGB-S-010-T-00;2011-12.EN - Feed Water, Boiler Water and Steam Quality for Power Plants / Industrial Plants

- ASTM D1066 Standard practice for Sampling Steam

- ASTM D1192 / D3370 Standard Guide for Equipment and Practices for Sampling Water and Steam

- ASME PTC19.11 The specification requires a ""isokinetic sample nozzle" for representative sampling of the specific two-phase saturated steam flow via sample ports drilled in the side of the nozzle facing the steam flow.

- SO 5667.7 Water Quality-Sampling – Part 7: Guidance on sampling of water and steam in boiler plants

- PED 2014/68/EU - Pressure Equipment Directive

- DIN EN 12952 - Water-tube boilers and auxiliary installations

- DIN EN 12953 - Shell boilers

Steam and Water Analysis System (SWAS) are designed for continuous monitoring and control of water and steam purity in the boiler plant cycle.

The SWAS sampling system shall obtain samples from steam and water pipelines which shall be adequately conditioned and flow through water analysers for continuous analysis and provide parallel facility for grab sampling.

The analyser outputs signals shall be used for continuous monitoring of various parameters like analysis of pH, Specific Conductivity, Cation Conductivity, Degassed Conductivity, Sodium, Silica, Dissolved Oxygen, Phosphate, Chlorides, TOC etc.

Analyser signals will be transported to central DCS systems where process operators can monitor and optimize the boiler cycle process.

At least two signals will be used to read the analyser measurement and check the healthy of analyser sensor;

- Analog outputs signal (typical 4-20 mA) for each parameter for monitoring the steam/water quality.

- Alarm with potential free contacts for all significant parameters measurements which exceed their permissible limits including those of sample conditioning system.

State-of-the-art systems are provided with bus communication (e.g. Profibus or Modbus), the advantage of bus communication systems are, you need only a couple of wires, the lower cost and saving of cabling, more instrument detail information available (sample flow, temperature, sensor healthy, status, error messages, etc.

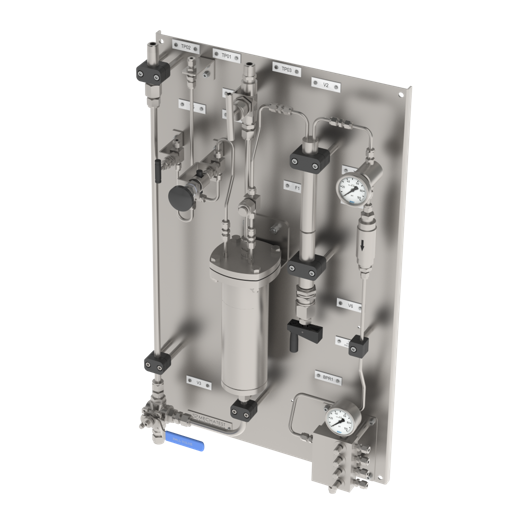

Sample Conditioning Panels are designed for proper conditioning of your steam and water samples. We take care from sample tap to sampling conditioning and analysis.

Mechatest standard sample conditioning panels for steam and water sampling purposes, the conditioning systems has the main function to reduce and regulate the temperature, flow and pressure of the sample. This kind of sampling panels are mostly used in combination with water analyser equipment for analysis on chemical parameters like conductivity, pH, dissolved Oxygen, Silica, Sodium etc.

The panels are designed with best quality products for safe operation and representative sample at the desired pressure and temperature.

From the international guidance ASME PTC 19.11 Steam and Water Sampling, Conditioning, and Analysis in the Power Cycle, Mechatest is taking care of the following sections;

- Section 2: Sample Point and Analysis Selection Criteria

- Section 3: Obtaining the Sample (we can make probe vibration calculations and help you select standard or Isokinetic sampling nozzle)

- Section 4: Transporting the Sample (we can make lagtime, liquid velocities and pressure loss calculations and help you select best sample transport tube sizing in combination with the desired sample flow rate)

- Section 5: Sample Conditioning

- Section 6: Sample Analysis and Instrumentation (we are independent and can select best analyser fabricate and analysis for your application in general purpose area or Explosion proof area)

SWAS Guidelines and Directives

- ASME PTC 19.11-2008 Steam and Water Sampling, Conditioning, and Analysis in the Power Cycle

- VGB/DGRL, VGB S-006 Sampling and Physico-Chemical Monitoring of Water and Steam Cycles

- VGB-S-010-T-00;2011-12.EN - Feed Water, Boiler Water and Steam Quality for Power Plants / Industrial Plants

- ASTM D1066 Standard practice for Sampling Steam

- ASTM D1192 / D3370 Standard Guide for Equipment and Practices for Sampling Water and Steam

- ASME PTC19.11 The specification requires a ""isokinetic sample nozzle" for representative sampling of the specific two-phase saturated steam flow via sample ports drilled in the side of the nozzle facing the steam flow.

- SO 5667.7 Water Quality-Sampling – Part 7: Guidance on sampling of water and steam in boiler plants

- PED 2014/68/EU - Pressure Equipment Directive

- DIN EN 12952 - Water-tube boilers and auxiliary installations

- DIN EN 12953 - Shell boilers

VGB S-006 most common guideline for European market

The Standard VGB-S-006-00-2012-09-EN is intended to supplement VGB-S-010-T-00;2011-12.EN Standard for Feed Water, Boiler Water and Steam Quality for Power Plants / Industrial Plants (formerly VGB Standard VGB-R-450-Le) and to give recommendations for the correct positioning, design and instrumentation as well as for the maintenance of measuring equipment in the water/steam cycle.

This is the first time that comprehensive recommendations for sampling and physico-chemical monitoring of water/steam cycles have been established. Supplementary information relating to chemical monitoring can be found in other rules and standards.

This VGB standard has been established in close co-operation with power plant users, power plant manufacturers (OEMs for boilers/turbines), measuring instrument manufacturers as well as firms providing analytical services on the power plant sector. This standard represents the state-of-the-art.

Samples must be taken from locations that are representative of the water source, treatment plant, storage facilities, distribution network, points at which water is delivered to the consumer, and points of use. In selecting sampling points, each locality should be considered individually; however, the following general criteria are usually applicable:

Sampling points should be selected such that the samples taken are representative of the different sources from which water is obtained by the public or enters the system.

These points should include those that yield samples representative of the conditions at the most unfavourable sources or places in the supply system, particularly points of possible

contamination such as unprotected sources, loops, reservoirs, low-pressure zones, ends of the system, etc.

Sampling points should be uniformly distributed throughout a piped distribution system, taking population distribution into account; the number of sampling points should be proportional to the

number of links or branches.

The points chosen should generally yield samples that are representative of the system as a whole and of its main components.

Sampling points should be located in such a way that water can be sampled from reserve tanks and reservoirs, etc.

In systems with more than one water source, the locations of the sampling points should take account of the number of inhabitants served by each source.

There should be at least one sampling point directly after the clean-water outlet from each treatment plant.

Isokinetic Sampling Probes For Steam Applications

- EPRI Isokinetic Sampling Nozzles (Probes)

- ASME PTC 19.11 The specification requires a "isokinetic sample nozzle" for representative sampling of the specific two-phase saturated steam flow via sample ports drilled in the side of the nozzle facing the steam flow.

-

Recommended ONLY for saturated steam in steam boiler and power plants, for superheated steam (only if particulates are measured), isokinetic sampling is

normally not required for water samples.

Click here and see our standard sample probes for non-isokinetic sampling.

- These nozzles meet also the requirements of ASTM Standards D1066 and D3370.

- The nozzles extract a representative isokinetic sample from a flow region removed from the pipe surface and at the average flow velocity of the sample fluid.

- This arrangement results in the withdrawal of the sample with representative concentrations of dissolved, suspended, and volatile constituents.

- An appropriate nozzle (probe) is designed for the desired sample flow and typical conditions of the sample fluid. When the flow velocity through the pipe changes, sample flow should be adjusted to maintain isokinetic sampling.

- Each Nozzle (probe) is designed with considerations of vortex shedding, resonance, vibration, erosion, and strength of the attachment to the pipe.

Be part of the best solution, it all starts with you!

We make sampling solutions helping to protect the environment now and for future generations, together we can make a difference.

| Doedijns - Mechatest Sampling Solutions | Vydraulics Group | Vremac | Sypack | |

| Bleiswijkseweg 51 | Telephone & Email | Hydropack | Koppen & Lethem | |

| 2712 PB Zoetermeer | +31(0)88 091 2811 | Vapo | GDM | |

| The Netherlands | sales.mechatest@vydraulics.com |