Sampling Product Selector

Open or closed sampling solutions

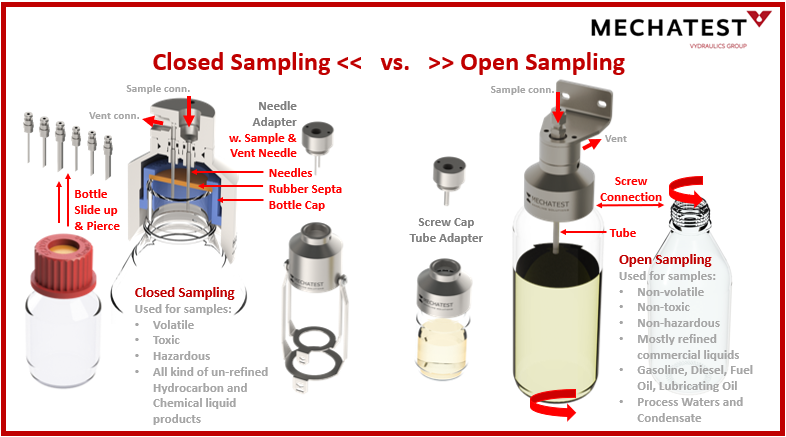

To ensure the integrity and reliability of test results on your sample analysis, proper sampling techniques are important. The first selection you have to make is, are you going to sample in an “open” or “closed” sample container?

Hydrocarbon or chemical samples are normally sampled in CLOSED SAMPLING systems and containers.

The OPEN SAMPLING systems are normally used for non-volatile, non-toxic and non-hazardous samples.

CLOSED SAMPLING systems are designed for:

- To sample liquids or gasses free from emissions to the atmosphere.

- The person who take the sample cannot breathe harmful substances.

- The sample stays in closed container, prevent evaporating lighter products.

- Prevent waste and pollution to environment.

- Safe for your health & environment, safe for sample.

- Bottle samplers are with needle adapter (bottle + cap + septa), the process and vent needle are pierced through the septa, this forms a closed loop sampling solution.

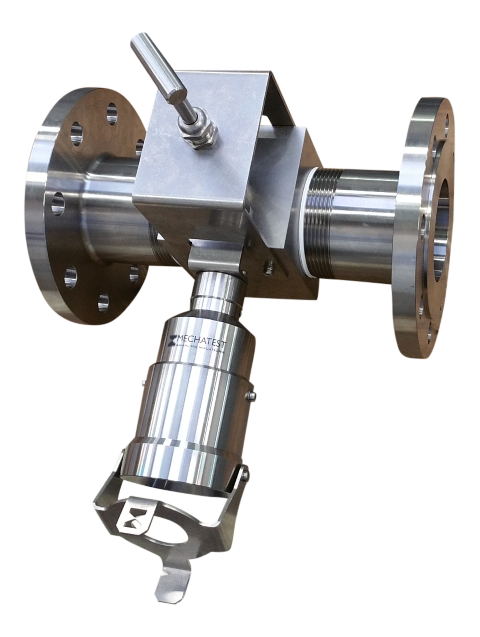

- Higher pressure liquids and gasses sampled with sample cylinder.

Samples in petroleum refineries, petrochemical complexes and chemical industry are either flammable or hazardous.

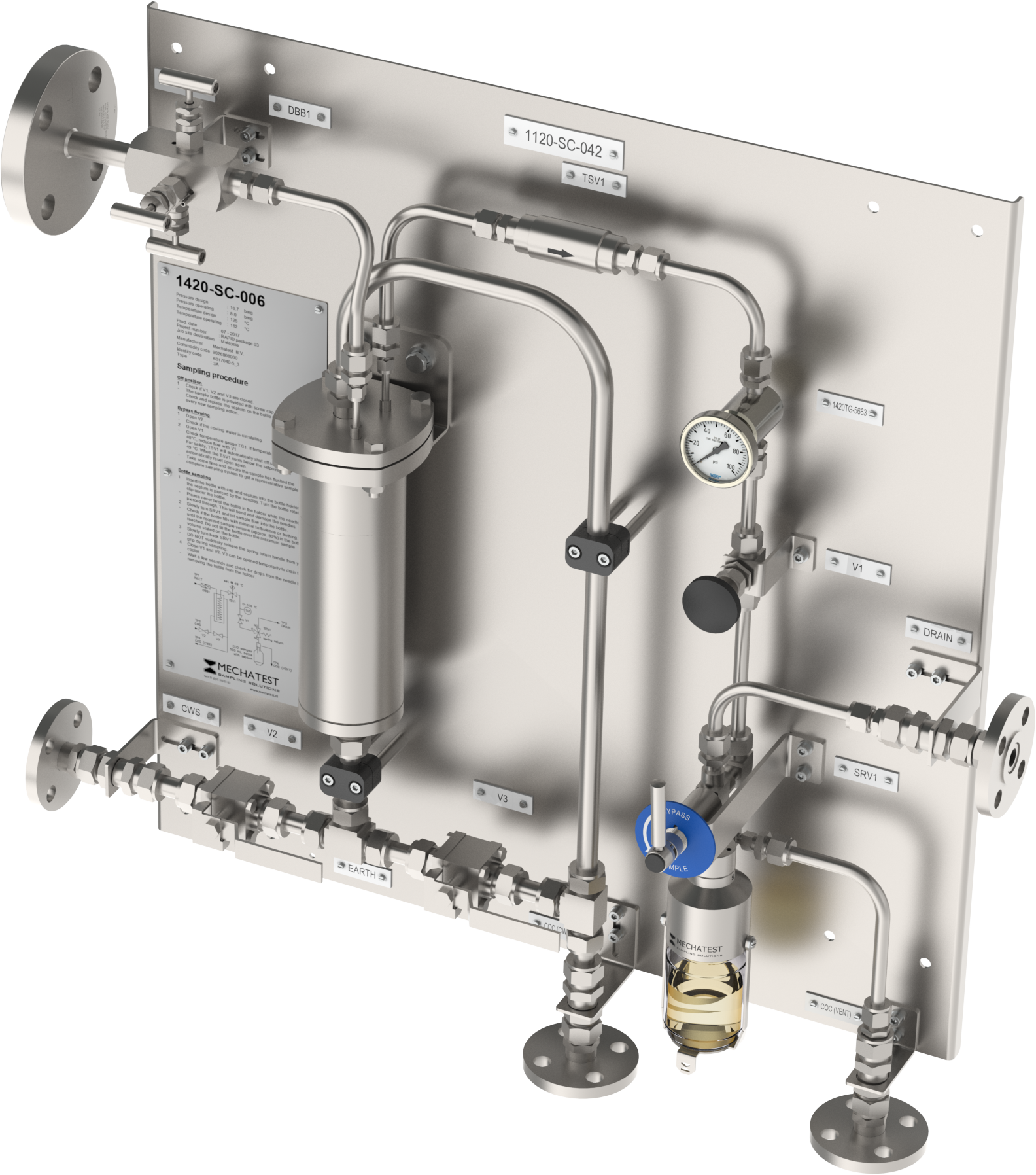

These sampling systems are designed to handle a wide range of fluids like:

- Petroleum liquids

- Low and high pressure liquid and gasses

- Cold and hot flashing liquids

- Toxic fluids

- Hazardous fluids with high vaporization pressures

- Dangerous and volatile substances

OPEN SAMPLING systems are based on:

- System design to sample only liquids with open connection to atmosphere when bottle is take out of the sampler.

- The person who take the sample can exposed to sample vapors.

- The sample stays in open container when sampling, after sampling to container can be closed with cap.

- Splashing can occur, possibility for waste and pollution to environment.

- Sampling with tubes in open bottle or by using a sample screw adapter and offers (only) zero emission during the filling of the bottle. With bottle screw adapter local spillage can be avoided.

- Using type sample bottle adapter for screw the bottle into the holder.

The “open” type sampling systems are normally used for:

- Non-volatile

- Non-toxic,

- Non-hazardous samples

- Mostly refined (commercial) gas oil, diesel oil, fuel oil, lubricating oil, process water and condensate samples.

In preparing this procedure the following reference was consulted: ASTM D4057 and ASTM D1265-05.

Cross Reference list

Be part of the best solution, it all starts with you!

We make sampling solutions helping to protect the environment now and for future generations, together we can make a difference.

| Doedijns - Mechatest Sampling Solutions | Vydraulics Group | Vremac | Sypack | |

| Bleiswijkseweg 51 | Telephone & Email | Hydropack | Koppen & Lethem | |

| 2712 PB Zoetermeer | +31(0)88 091 2811 | Vapo | GDM | |

| The Netherlands | sales.mechatest@vydraulics.com |