FPSO Liquid & Gas Sampling Systems

FPSO topside sampling systems

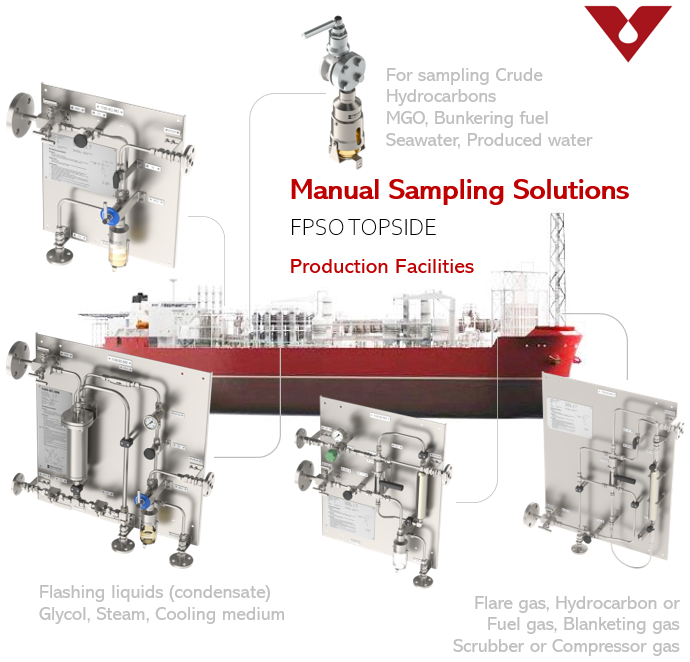

Manual sampling panels for liquid, gas and liquefied gas applications specific for the FPSO topside production facilities.

Floating Production Storage and Offloading (FPSO) units in the oil & gas industry produces and stores a huge quantity of hydrocarbons from offshore

deep-water wells. Specific for the FPSO industry we designed a complete range of sampling solutions to collects all kind of production fluids like crude, hydrocarbon liquid and gas samples,

bunkering fuels, process waters, steam, seawater, and cooling medium.

- The FPSO industry ask for more than only SS316 material requirements, Super Duplex (SDSS), 6MO or Inconel materials are more common, challenges but it means a longer production lifetime for those FPSO vessels, maximizing their capacity and their operator safety.

- Sample volumes cylinders 150, 300, 500, 1000 and 2250 ml (other on request)

- Max. Process Pressure 124 barg (1800 psig), 345 barg (5000 psig) or 689 barg (10000 psig)

- Safe (sampling) Process Temperature 60°C (140°F), high temperature with sample cooler

- Complete sampling systems available in 316 stainless steel, Monel, Inconel, Incoloy, Hastelloy, Duplex (other on request)

- Cylinders conform European “Transportable Pressure Equipment Directive 99/36/EC” (TPED) or “Shipping Container Specifications” DOT from the U.S.

- One-handle operation by multiple valves guarantees simple operation and easy sample taking without complicated sampling procedures

- Purge options available

-

Sampling systems with NACE MR0175 or NACE MR0103 standards for sour gas (H2S) applications.

Floating Production Storage and Offloading (FPSO) units in the oil & gas industry produces and stores a huge quantity of hydrocarbons from offshore deep-water wells. Specific for the FPSO industry we designed a complete range of sampling solutions to collects all kind of production fluids like crude, hydrocarbon liquid and gas samples, bunkering fuels, process waters, steam, seawater, and cooling medium. In the offshore industry, the equipment (meaning the systems and their components) must be able to withstand the most severe conditions, such as temperature variations, the saltiness of seawater resulting in corrosion and often a hefty number of vibrations on top of that. In this FPSO oil and gas industry it has become very important to design high-end but also cost-saving sampling solutions for extreme process and environmental conditions.

- Closed Loop and Emission Free Sampling

- Safer for the operator and environment, prevent pollution

- Safer for the sample and safe sample

- Easy in operation and Low maintenance

- Spring Return Handles available for Swagelok, Fitok and Hoke ball-valves.

- Options: Spring return handle on sample valve, panel-mounted and protection cabinets with heater, floor-stands, special elastomers on request, all kind of process connections, sample coolers

Applications will found in the Petrochemical and Chemical industry, products to be sampled are;

- Acetylene samples

- Butane samples

- Ethylene samples

- Flue gas samples

- Natural gas samples

- LPG samples

- Propylene samples

- Chemical mixture samples

- Hydrocarbon samples

- Liquefied gas samples

- Liquid flashing samples

- etc.

- ASTM D 4057

- ASTM D1265-05

- NACE MR0175 or MR0103

For sampling Crude Hydrocarbons, MGO, Bunkering fuel, Seawater, Produced water, Flashing liquids (condensate) Glycol, Steam, Cooling medium, Flare gas, Hydrocarbon or Fuel gas, Blanketing gas Scrubber or Compressor gas.

Your business benefits

- Maximizing long run FPSO capacity and their operator safety

- Taking representative samples and get better results

- Product quality control, reducing costs by process optimization

- Preventing production loss

- Closed loop sampling, zero emission, safe for operator health & environment

- Safe, high pressure sampling up to 689 barg (10.000 PSI)

Sampling for FPSO topside production facilities

In the offshore industry, the equipment (meaning the systems and their components) must be able to withstand the most severe conditions, such as temperature variations, the saltiness of seawater resulting in corrosion and often a hefty number of vibrations on top of that. In this FPSO oil and gas industry it has become very important to design high-end but also cost-saving sampling solutions for extreme process and environmental conditions.

In the lead with our own sampling products

Mechatest and Doedijns part of the Vydraulics group has a long history with thousands of oil & gas sample application references, we designed our own unique liquid sampler products for closed sampling who are best innovative on the market compared to our competitors, gives us independency, better prices, and delivery times.

Independency makes the BEST sampling solution

The FPSO industry ask for more than only SS316 material requirements, Super Duplex (SDSS), 6MO or Inconel materials are more common, challenges but it means a longer production lifetime for those FPSO vessels, maximizing their capacity and their operator safety.

As an independent manufacturer our main activities are the complete design, pre-FEED process advises, detail engineering, procurement, assembly, commissioning, and service activities, with our 30+ years of sampling experience we are a useful supplier for your sampling needs.

Co-operation with major suppliers and international well-known fabricates of components, our know-how acquired in sampling designing and manufacturing make us unique and capable of providing its clients with the "best" solution, both in technical and economic terms.

Safety accessories

- Spring return handles on valves

- Safety relief devices for overpressure protection

- Activated carbon filters on the venting outlet

- Venting solutions to release pressure on the quick connectors or purging

- Sample station enclosures GRP, Stainless Steel, Coated with offshore painting specifications

MOBILE / TRANSPORTABLE SAMPLING SOLUTIONS FOR FPSO

If there is no posiblility (for any reason) to place fixed mounted sampling points, the FPSO mobile (transportable) sampling solution is the better choice for you!

This is a custom made and money safe solution, we design for every application a portable sampling system for gas or liquid sampling on

topside production facilities.

Mobile (transportable) sampling solutions carry with easy a several sample cylinders to the different sample tap points in your plant area.

- For applications with over-pressure or vacuum, high or low temperature, liquids or gas

- Optional with vacuum pump for low pressure (vacuum) sample applications

- Explosion proof

Be part of the best solution, it all starts with you!

We make sampling solutions helping to protect the environment now and for future generations, together we can make a difference.

| Doedijns - Mechatest Sampling Solutions | Vydraulics Group | Vremac | Sypack | |

| Bleiswijkseweg 51 | Telephone & Email | Hydropack | Koppen & Lethem | |

| 2712 PB Zoetermeer | +31(0)88 091 2811 | Vapo | GDM | |

| The Netherlands | sales.mechatest@vydraulics.com |