Steam & Water Analysis Systems (SWAS)

Steam sampling and analysis solutions - SWAS

Mechatest is well known for it’s excellent quality steam and water sampling and analysis solutions SWAS built as per ASME PTC 19.11, VGB S-006 and ASTM D5540.

The Steam/Water Analysis Systems (SWAS) are designed conform latest modern technology and has been continuously improved to keep the reability of your water steam analysis safe at all times and to protect your power plant from corrosion and scaling, suitable for power plant chemistry.

Steam and Water Analysis System (SWAS) are designed for continuous monitoring and control of water and steam purity in the boiler plant cycle and at other important analysis points. The SWAS sampling system shall obtain samples from steam and water pipelines which shall be adequately conditioned and flow through water analysers for continuous analysis and provide parallel facility for grab sampling.

The analyser outputs signals shall be used for continuous monitoring of various parameters like analysis of pH, Specific Conductivity, Cation Conductivity, Degassed Conductivity, Sodium, Silica, Dissolved Oxygen, Phosphate, Chlorides, TOC etc.

After selecting the analysers and designing the sample systems it is very important to choose the environment for the complete system.

- Built as per standard European VGB S-006 and International guidance ASME PTC 19.11 and ASTM D5540 Steam and Water Sampling, Conditioning, and Analysis in the Power Cycle.

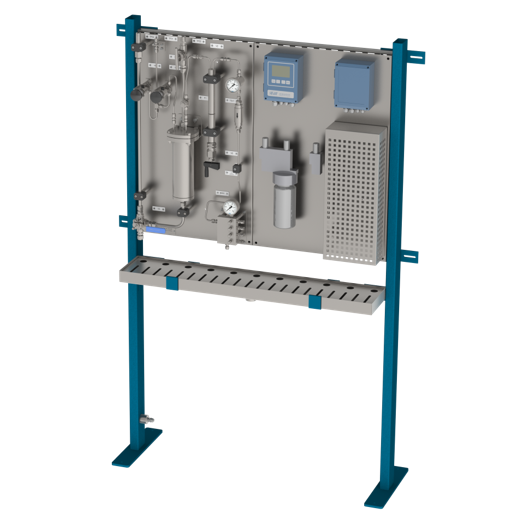

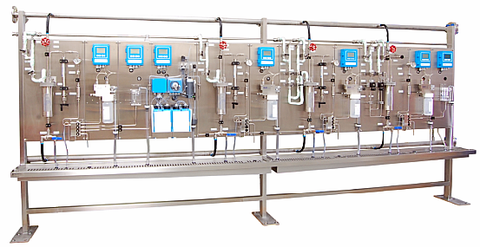

- Compact open rack design with best selection of top of the world fabricate components and analysers, designed with the ease of maintenance in mind.

- Operator friendly with validation and calibration facilities at one side of the SWAS rack.

- Efficient temperature cooling with Sentry sample coolers, pressure reduction with Sentry VREL and flow control.

- Grab sample capability.

- Including Swan Back Pressure Regulator BPR for constant pressure and sample flow for up to 4 water analyzer applications.

- Custom options are available to fit your needs.

- Manufactured by Mechatest Sampling Solutions.

As an independent System Integrator our main activities are the complete design, engineering, procurement, assembly and integration of steam and water sampling, conditioning, and analysis systems for the power cycle industry, we design accordingly to VGB/DGRL and ASME PTC 19.11 which discuss the methods and instrumentation for testing boiler make-up and feedwater, steam, and condensate in relation to performance testing.

Steam and Water Analysis Systems - SWAS analyser racks and containers. Steam Sample Conditioning and Collection. Sampling solutions for steam & water sampling. Sample Conditioning Panels built as per standard ASME PTC 19.11 and VGB/DGRL. For proper conditioning of your steam and water samples. Steam apllications Demi Water, Feedwater, Condensate, Boiler Water, LP Drum Water, LP/HP Steam, Life Steam, Main Steam Demi Water, Feedwater, Condensate, Boiler Water, LP Drum Water, LP/HP Steam, Life Steam, Main Steam for power stations. Representative steam samples, Contamination free process and Custom build solutions. Control Your Steam Quality, increase lifetime of your steam applications, prevent corrosion in boilers and pipelines.

- Reliable / stable measurement

- A good working environment for monitoring and maintenance

- Lower maintenance costs

- Longer lifespan of the equipment, etc.

- In a lot of cases a “walk-in” shelter is a very good and durable solution.

- Quality Analyzer systems, Perfectly tailored to your individual requirements

- Steam and Water Analysis System (SWAS), Analysis of pH, Conductivity, Silica, Sodium, Dissolved Oxygen, Phosphate, Chlorides, TOC for power stations

- etc.

- ASME PTC 19.11 Steam and Water Sampling, Conditioning, and Analysis in the Power Cycle

- ASME PTC 19.11-2008 Steam and Water Sampling, Conditioning, and Analysis in the Power Cycle

- VGB/DGRL, VGB S-006 Sampling and Physico-Chemical Monitoring of Water and Steam Cycles

- VGB-S-010-T-00;2011-12.EN - Feed Water, Boiler Water and Steam Quality for Power Plants / Industrial Plants

- ASTM D1066 Standard practice for Sampling Steam

- ASTM D1192 / D3370 Standard Guide for Equipment and Practices for Sampling Water and Steam

- ASME PTC19.11 The specification requires a ""isokinetic sample nozzle" for representative sampling of the specific two-phase saturated steam flow via sample ports drilled in the side of the nozzle facing the steam flow.

- SO 5667.7 Water Quality-Sampling – Part 7: Guidance on sampling of water and steam in boiler plants

- PED 2014/68/EU - Pressure Equipment Directive

- DIN EN 12952 - Water-tube boilers and auxiliary installations

- DIN EN 12953 - Shell boilers

Corrosion is the enemy. A good SWAS is your defense

Corrosion is the enemy that threatens every metal surface in a power plant. Keeping water chemistry in balance is the only way to keep corrosion under control.

The days of grab sample analysis are over. The key to plant safety in today’s environment is on-line analysis of steam and water at different points in the power plant steam cycle, some of

most important analysis are;

-

pH

Analysis of pH helps detect changes that impact the effectiveness of closing and potential corrosion of the boiler tubes. -

Conductivity

Provides an indication of total dissolved solids and susceptibility to scaling. -

Dissolved oxygen

Monitoring of dissolved oxygen level helps to keep the corrosion in check as, dissolved oxygen analysis help to monitor the efficiency of the deaerator. -

Silica

Silica volatizes in steam and it is carried into the turbine. Although the silica deposits are not corrosive, but they severely reduce the efficiency. -

Hydrazine

It works as an oxygen scavenger, destroying traces of dissolved oxygen. Hydrazine is also passivating agent and produces a protective oxide coating on metal tube wall.

Steam Sample Points and Analysis Locations in Power Plants

Steam and Water Analysis System (SWAS) are designed for continuous monitoring and control of water and steam purity in the boiler plant cycle and at other important analysis points.

The analyser outputs signals shall be used for continuous monitoring of various parameters like analysis of pH, Specific Conductivity, Cation Conductivity, Degassed Conductivity, Sodium, Silica, Dissolved Oxygen, Phosphate, Chlorides, TOC etc.

In the steam boiler cycle of power plants we find the following locations for monitoring and control the steam and water samples;

- Demi Water

- Feedwater

- Condensate

- Boiler Water

- LP Drum Water

- LP/IP/HP Steam

- Life Steam

- Saturated Steam

- Superheated Steam

- Reheated Steam

- Main Steam

- Feedwater

| Analysis | Makeup | Condensate |

Pol. Eff. |

Dearator IN |

Dearator OUT |

Feedwater | SG Water |

Saturated Steam |

Superheated Steam |

| Spec. Conductivity | N | N | N | N | N | N | |||

| Cat. Conductivity | L | N | N | N | L/N | L | |||

| DG Cat. Conductivity | L | L | |||||||

| pH | L | N | N | N | N | ||||

| Sodium | N | N | N | N | L/N | N | L | ||

| Silica | N | N | N | N | N | N | L | ||

| Disolved Oxygen | L | N | L | N | N | L | |||

| Oxygen Scavenger | N | L/N | R | ||||||

| Iron | N | L | N | S | L | R | |||

| Copper | N | L | N | S | L | L | |||

| TOC | L | L | L | ||||||

| Hardness | L | L | |||||||

| Ammonia/Amine | N | N | L | ||||||

| Chloride | L | L | L | L | L | ||||

| Sulfate | L | L | L | L | L | ||||

| Phosphate | N | ||||||||

| Table ASME PTC 19.11 |

N = Normal, recommend continious (online) analyser measurements

L = Less common, recommend sharing (online) analysis or measurement with portable analyser

R = Rare or occasional, recommend measurement with portable analyser

S = Less common except at startup, recommend measurement with portable analyser

~0.2%

Only for investment of a SWAS system on total plant cost

>35bar

Use always piston type VREL pressure valve in sample line

>50°C

Use thermal shutoff valve TSV for analyser safety protection

~30 kW

Cooling power required per steam samle line for water analysis

Predesigned SWAS skid system for water condensate measurement applications conform;

- ASME PTC 19.11-2008 Steam and Water Sampling, Conditioning, and Analysis in the Power Cycle

- VGB/DGRL, VGB S-006 Sampling and Physico-Chemical Monitoring of Water and Steam Cycles

- VGB-S-010-T-00;2011-12.EN - Feed Water, Boiler Water and Steam Quality for Power Plants / Industrial Plants

- ASTM D1066 Standard practice for Sampling Steam

- ASTM D1192 / D3370 Standard Guide for Equipment and Practices for Sampling Water and Steam

- ASTM D5540 Standard Practice for Flow Control and Temperature Control for On-Line Water Sampling and Analysis

- ASME PTC19.11 The specification requires a ""isokinetic sample nozzle" for representative sampling of the specific two-phase saturated steam flow via sample ports drilled in the side of the nozzle facing the steam flow.

- SO 5667.7 Water Quality-Sampling – Part 7: Guidance on sampling of water and steam in boiler plants

- PED 2014/68/EU - Pressure Equipment Directive

- DIN EN 12952 - Water-tube boilers and auxiliary installations

- DIN EN 12953 - Shell boilers

Samples must be taken from locations that are representative of the water source, treatment plant, storage facilities, distribution network, points at which water is delivered to the consumer, and points of use. In selecting sampling points, each locality should be considered individually; however, the following general criteria are usually applicable:

Sampling points should be selected such that the samples taken are representative of the different sources from which water is obtained by the public or enters the system.

These points should include those that yield samples representative of the conditions at the most unfavourable sources or places in the supply system, particularly points of possible

contamination such as unprotected sources, loops, reservoirs, low-pressure zones, ends of the system, etc.

Sampling points should be uniformly distributed throughout a piped distribution system, taking population distribution into account; the number of sampling points should be proportional to the

number of links or branches.

The points chosen should generally yield samples that are representative of the system as a whole and of its main components.

Sampling points should be located in such a way that water can be sampled from reserve tanks and reservoirs, etc.

In systems with more than one water source, the locations of the sampling points should take account of the number of inhabitants served by each source.

There should be at least one sampling point directly after the clean-water outlet from each treatment plant.

Be part of the best solution, it all starts with you!

We make sampling solutions helping to protect the environment now and for future generations, together we can make a difference.

| Doedijns - Mechatest Sampling Solutions | Vydraulics Group | Vremac | Sypack | |

| Bleiswijkseweg 51 | Telephone & Email | Hydropack | Koppen & Lethem | |

| 2712 PB Zoetermeer | +31(0)88 091 2811 | Vapo | GDM | |

| The Netherlands | sales.mechatest@vydraulics.com |