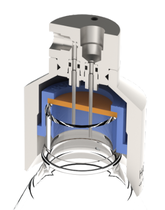

Back Purge Liquid Sampler

Liquid Sampler Back Purge configuration

MBS-A4

Mechatest Bottle Sampler with Back Purge configuration is a combination of a 3-way valve, liquid bottle sampler and purge system. Based on single process, sample flow back purge and vent connection. The better solution for representative sample take-off when bypass flow is not possible.

Liquid sampler that can take spot samples in a number of single phase liquid applications under vacuum, atmospheric and low pressure.

This typical “needle” bottle sampler for liquids is closed loop and suitable for emission free sampling of toxic, dangerous or volatile liquids. Modular and with a dozen of interchangeable

options.

Highest quality and best economical liquid sampler on the market.

- Sample volumes 50, 100, 250, 500 and 1000 ml (other on request)

- Max. Process Pressure 8 barg (116 psig)

- Max. Vapor Pressure 0.7 barg (10 psig)

- Safe (sampling) Process Temperature 60°C (140°F), high temperature with sample cooler

- Available in 316SS, Monel, Hastelloy, Duplex, or chemical resistance plastic TFM or PVC (other on request)

- Replaceable bottle holder makes the sampler very flexible, possibility to change later from bottle volume

- Bottle holders for GL32 and GL45 thread bottles with screw cap and septum

- Bottle adapters also for Dopak bottles and specific client bottles

-

Sampling systems with NACE MR0175 or NACE MR0103 standards for sour liquid (H2S) applications.

Single handle operation with an instrumentation (small volume) 3-way valve, this back purge sampler enables to purge with inert gas the sample flow backwards, if a bypass (circulation) sample flow is not possible you need to refresh and flush old sample back from all the dead volumes in the sample system (sample transport line, process valve and sample probe) After back purging the sample system will fill with new sample and the collection of a representative liquid process sample can be done, typical for applications where bypass sample flow is not possible, direct mount to the process pipeline or an easily accessible workplace for operation or laboratory personnel. The back purge sampler is a good solution to prevent dead volume of sample.

Easy sampling procedure, turn the sample valve to BACK FLOW, the purge gas will push the old sample back, after certain time turn the sample valve to SAMPLE, the sample will flow into the sample bottle under system pressure, while air and gasses in the bottle are vented through the vent connection. When the required volume of approx. 80% of the bottle volume is taken, turn the sample valve in OFF position, the sampling procedure is completed.

The sample bottle holder consists of a bottle adapter with a process and vent needle, the sample bottle is sealed with cap and septa. This “needle” type bottle sampler is a closed loop system and enable operators to obtain samples of liquids, hazardous or toxic. The spot sample collected in a sample bottle is more safe and easy for transportation to the lab.

Use "spring return handle" on the sample valve to protect personnel and prevent unnecessary sample waste. The spring return handles also known as “deadmans” handles, always "spring" return to closed position when the handle will be released.

- Most innovative liquid bottle sampler solution on the market

- Modular and with a dozen of interchangeable options

- Closed Loop and Emission Free Sampling

- Safer for the operator and environment, prevent pollution

- Safer for the sample and safe sample

- Easy in operation and Low maintenance

- Option for second bottle retaining clip and use the sampler with two kind of bottle volumes (eg. bottle waste sample)

- Spring Return Handles available for Swagelok, Fitok and Hoke ball-valves.

- Options: Spring return handle on sample valve, panel-mounted and protection cabinets with heater, floor-stands, special elastomers on request, all kind of process connections, sample coolers

- Single phase liquid samples

- Toxic liquid samples

- Dangerous liquid samples

- Volatile liquid samples

- Mostly refined (commercial) gas oil, diesel oil,fuels, lubricating oil

- Water / condensate samples (tap, brackish, saline, demi)

- All samplers can comply with NACE MR-01-75 / MR-01-03 standards, for sour liquid sample applications.

- Acid samples • Amine samples • Alcohols • Aromatics • Benzene • Bio-fuel • Brine Water • Chemical mixture • Cumene • DCE (DiChloorEthaan) • Glycol • Gasoline • Hydrocarbons • Ketone • Kerosene • Naphtha • Paraffins • Solvents • Toluene • Xylene • etc.

- ASTM D 4057

- ASTM D1265-05

- NACE MR0175 or MR0103

- Safety sleeve around bottle (SS316 or POM)

- Spring return handles on valves

- Safety relief devices for overpressure protection

- Lockable handles

- Activated carbon filters on the venting outlet

- On mounting plate or in protection enclosures

- Drain or drip trays with flange connections

- Connection types and sizes

- Various materials

Be part of the best solution, it all starts with you!

We make sampling solutions helping to protect the environment now and for future generations, together we can make a difference.

| Doedijns - Mechatest Sampling Solutions | Vydraulics Group | Vremac | Sypack | |

| Bleiswijkseweg 51 | Telephone & Email | Hydropack | Koppen & Lethem | |

| 2712 PB Zoetermeer | +31(0)88 091 2811 | Vapo | GDM | |

| The Netherlands | sales.mechatest@vydraulics.com |